| Model | Fuel Type | Rated Capacity (kg) | Load Centre (mm) | Tyres | Mast (m) | Turning Radius (mm) |

|---|---|---|---|---|---|---|

| FG18HT-21 | LPG/Petrol | 1750 | 500 | Puncture Proof or Pneumatic | Full range | 1990 |

| FD18T-21 | Diesel | 1750 | 500 | Puncture Proof or Pneumatic | Full range | 1990 |

Great design starts on the smallest level and with the Komatsu AX50, no detail has been overlooked. Building on our 80-year history of superior engineering, the AX50 delivers improved performance and unbeatable strength for your most demanding applications.

Great design starts with the Komatsu AX50 Series of Gas Forklift and Diesel Engine Forklift. With our 80-year history and Komatsu’s reliability of superior engineering, no detail has been overlooked.

The AX50 series delivers the qualities you’ve come to count on in a Komatsu, exceptional performance, increased productivity, reduced operating costs, trusted safety features and unbeatable power for the most demanding jobs.

Reduced Operating Costs

- Optimum lubrication intervals

- Simple maintenance for greater efficiency

- The AX50 Fully Hydrostatic Power Steering system reduces operator fatigue by eliminating kickback and allowing easy steering, even while the forklift is stationary. A small-diameter steering wheel improves operator feel and control.

- A new transmission, designed and manufactured by Komatsu Forklift Limited, handles the high torque provided by the powerful K21 engine. A high-capacity oil cooler protects the torque converter, and an aluminum alloy transmission case improves heat dissipation.

- O-ring face seals designed for high-temperature, high-speed applications reduces the possibility of leaks in the pump, power steering circuit and torque converter cooler.

- Now, when you buy a new Komatsu forklift the warranty runs for 5 years or 10,000 hours operation (Subject to Komatsu Forklift Australia warranty terms & conditions).

Komatsu Reliability

- Frame structure and changes to the mast improve durability

- Exceptional Heat balance - The bell-shaped shroud concentrates cooling air into the radiator also enhances reliability during heavy operations.

Safety

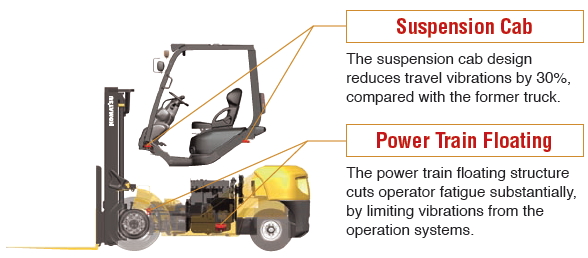

- The Komatsu Komfort Zone design uses a dual floating structure that protects operators. One set of vibration-dampening mounts separate the forklift’s frame from the engine and transmission. A second set of suspension mounts isolate the operator compartment from the frame. In addition, drive-train design reduces vibration transmitted from the differential. The combined technology of both of these Komatsu designed systems further reduce the vibrations transferred to the mast, fork, steering wheel and control lever, as well as the operator's seat. Therefore, ultimately improving operator comfort and cargo safety.

- Wide floor and open, non-slip step makes getting in and out easy and safe.

- Control levers designed for finger tip control

- Operator visibility is a key to productive forklift operations. The newly designed EZview mast and low-profile dash display gives an unrestricted view of the fork tips and surroundings. In the rear of the AX50, the upper corner of the counterweight angles sharply to give optimum visibility when moving in reverse.

- Komatsu Operator Presence System (KOPS) – standard on the AX50 – locks out lift, lower, tilt and traveling functions when the operator leaves the seat for more than three seconds. They do not resume until the operator returns to the seat and resets the controls. A flashing yellow warning light alerts the operator when the KOPS lock is activated. In addition, the forks cannot be lowered while the key is in the off position.

- Hot engine air and exhaust gases are tiring to the operator. On the AX50, angled ports aim hot engine air away from the operator while traveling in reverse. Exhaust vents located low on the counterweight keep exhaust gases away from the operator and also away from the floor to avoid stirring up dust.

- In the rear of the AX50, the upper corner of the counterweight angles sharply to give optimum visibility when moving in reverse.

- The sunken counterweight design in combination with the standard swing down gas bottle bracket allows for easy gas cylinder replacement with greater safety & risk of injury

|

|