FH Series 10 -16 Tonne Capacity Diesel Engine Hydrostatic Drive Forklift

Highlighting the advantages of using Komatsu forklifts in heavy-duty applications.

The Ultimate Guide to 16 Tonne Forklift Hire

| Model | Fuel Type |

Rated Capacity (kg) |

Load Centre (mm) |

Tyres | Mast (m) |

Turning Radius (mm) |

|---|---|---|---|---|---|---|

| FH100-1 | Diesel | 10000 | 600 | Puncture Proof or Pneumatic | Full range | 4200 |

| FH120-1 | Diesel | 12000 | 600 | Puncture Proof or Pneumatic | Full range | 4200 |

| FH135-1 | Diesel | 13500 | 600 | Puncture Proof or Pneumatic | Full Range | 4410 |

| FH160-1 | Diesel | 16000 | 600 | Puncture Proof or Pneumatic | Full Range | 4410 |

Whether you're a construction professional, warehouse manager, or logistics expert, understanding the ins and outs of 16-tonne Komatsu forklift hire will empower you to make informed decisions and maximize operational efficiency.

The new 10-16 tonne diesel hydrostatic drive family achieves its durability and low costs of ownership from its rugged designs and field proven components.

With Komatsu’s hydrostatic drive system, standard wet disc brakes, and Closed-center Load Sensing hydraulic system (CLSS), the Hydrostatic Lift Truck of the FH series achieves reduced costs of operation and reduced maintenance costs.

The FH series lowers your cost of operation in a variety of demanding, high-cycle operations.

Also equipped with KOMTRAX—Komatsu’s exclusive information data management system.

Komatsu Reliability

- Now, when you buy a new Komatsu forklift the warranty runs for 5 years or 10,000 hours operation (Subject to Komatsu Forklift Australia warranty terms & conditions).

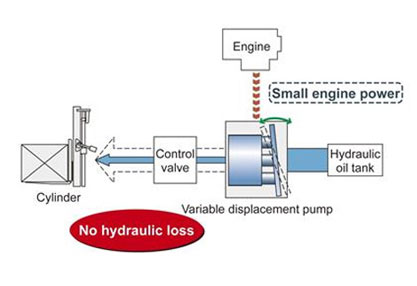

- Komatsu CLSS Hydrostatic Forklift and automatically detects the hydraulic load ensuring only the required amount of oil is supplied reducing unnecessary engine effort.

- 24 volt electrical components improve engine starting performance – even in cold regions the Komatsu FH will deliver smooth, consistent starting performance.

- High quality and Reliable Komatsu components. All of the Komatsu FH series main components such as the engine, hydraulic pumps, hydraulic motor, axles and controllers are designed, developed and manufactured by Komatsu.

- Komatsu Auto Engine Shutdown fitted standard.

- The Komatsu SAA4D107E-3 engine is U.S. EPA Tier 4 Final emission certified. Based on Komatsu proprietary technologies developed over many years, this new diesel engine reduces exhaust gas particulate matter (PM) by more than 90% as compared to Tier 4 Interim levels. This engines electronics and hydraulic components are all developed by Komatsu in-house and are designed to work together. Komatsu has achieved great advancements in technology, providing high levels of performance and efficiency in virtually all applications.

- Heavy-duty after treatment system. This new system combines a Komatsu Diesel Oxidation Catalyst (KDOC) and Selective Catalytic Reduction (SCR). The SCR NOx reduction system injects the correct amount of Diesel Exhaust Fluid (DEF) at the proper rate, thereby decomposing NOx into non-toxic water vapor (H20) and nitrogen gas (N2).

- Cooled Exhaust Gas Recirculation (EGR). Cooled EGR system recirculates a portion of exhaust gas into the air intake and lowers combustion temperature, thereby reducing NOx emissions. The system achieves a dynamic reduction of NOx, while reducing fuel consumption.

- Variable Geometry Turbocharger (VGT) system. Using Komatsu proprietary technology, a newly designed variable geometry turbocharger with a hydraulic accumulator is used to manage and deliver optimal air flow to the combustion chamber under all speed and load conditions, resulting in cleaner exhaust gas and improved fuel economy while maintaining performance.

- Komatsu Closed Crankcase Ventilation (KCCV). Crankcase emissions (Blowby gas) are passed through a KCCV filter, traps oil mist which is returned back to the crankcase for combustion. PM emission is reduced and results in cleaner exhaust gas.

- KOMTRAX, a standard feature on the FH series, is Komatsu’s remote equipment and fleet monitoring system. Leading-edge wireless technology and a secure, user-friendly web-based application provide critical information…anytime, anywhere. KOMTRAX tells us where your machines are, what they are doing, and how they are doing it providing total fleet management capabilities for improved fleet utilization, reduced downtime and lower owning and operating costs.

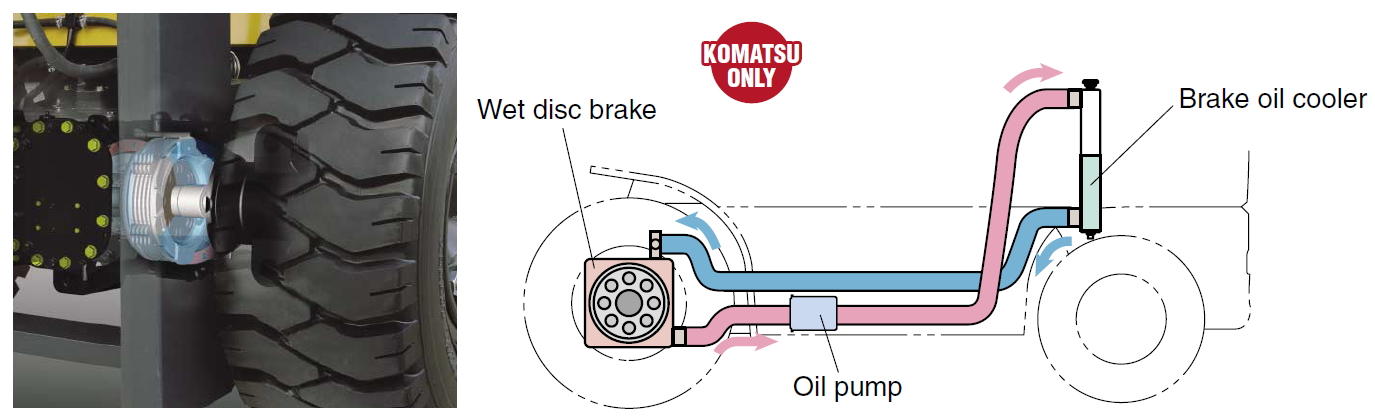

- The Oil Cooled wet disc braking system can withstand approx. 10 years or 10,000hrs without maintenance.The wet disc brake system is sealed with oil to block dust penetration, providing durable, water resistant and fade resistant characteristics. Smooth, stable braking provides productivity and reliability in demanding operations. The oil in a wet disc brake system is circulated through the brake oil cooler. This mechanism ensures stable braking under a heavy work load and prevents deterioration of the braking force that could be caused by raised oil temperatures.

The Ultimate Guide to 16 Tonne Forklift Hire - The Powerhouse: Introduction to 16 Tonne Komatsu Forklifts

- Determining Your Needs: Assessing Your Forklift Requirements

Understanding your specific lifting requirements and workload to determine if a 16-tonne Komatsu forklift is suitable.

Exploring the industries and applications where these forklifts excel.

Considering factors such as load capacity, lift height, maneuverability, and attachments.

- Benefits of 16 Tonne Komatsu Forklift Hire

Cost-effectiveness: Comparing the advantages of hiring a 16-tonne Komatsu forklift versus purchasing one.

Flexibility and scalability: Highlighting the convenience of renting a forklift based on project demands.

Access to the latest technology and equipment upgrades through rental options.

Maintenance and servicing: Discussing how forklift hire providers handle maintenance tasks, reducing downtime and costs.

- Selecting the Right 16 Tonne Komatsu Forklift Rental Company

Researching reputable forklift rental companies and understanding their expertise and track record.

Evaluating factors like rental terms, pricing, equipment availability, and customer support.

Reading customer reviews and testimonials to make an informed decision.

- Safety First: Operating 16 Tonne Komatsu Forklifts

Comprehensive guide on essential safety practices and regulations for operating a 16-tonne Komatsu forklift.

Explaining proper load handling techniques, stability considerations, and safety equipment.

Highlighting the importance of operator training and certification.

- Maximising Efficiency: Tips for Optimizing 16 Tonne Komatsu Forklift Performance

Best practices for improving productivity and minimising downtime.

Maintenance tips to ensure the forklift operates at peak performance.

Discussing advanced features and technologies that enhance efficiency and operator comfort.

Komatsu Safety

- Standard Travel Speed settings, 5, 8, 15 and 23.5 km/h settings.

- No Creeping – machine only moves when accelerator pressed

- Park Brake Alarm – leave the seat without the park brake and alarm sounds and dash light flashes

- Can change direction without releasing the accelerator pedal and without the switchback shocks of torque converter models.

- Rolling on ramps is controlled, preventing uncontrolled rolling back when stopped and enabling secure and smooth travel forward.

- Neutral start function and brake-linked start function. Machine will not start unless in Neutral and Brake applied

- Parking brake drag prevention function. Warning lamp flashes and Alarm sounds if you try and drive while the handbrake is engaged

- A simple load meter that allows the cargo weight to be measured in 10 kg steps is standard. If the load exceeds the set weight, the load meter sounds the buzzer to diminish the risk of exceeding the weight limit.

Anti Restart Function

- This function prevents the starter motor from turning again if the key is turned while the engine is already running, protecting against ring gear wear.

Optimal Performance

Komatsu’s CLSS hydraulic system has been utilized in our hydraulic excavators for many years. The load sensing capability automatically senses loading and the variable displacement pump then supplies only the amount of hydraulic fluid needed to do the job. This provides for much greater efficiency than conventional fixed displacement gear pumps, making good use of engine power to reduce overall fuel consumption.

Advantages include:

- Smooth traveling during hydraulic operations

- Superior productivity, especially when attachments are used

- No need to rev engine when using hydraulics

- Reduced fuel consumption

Komatsu Hydrostatic

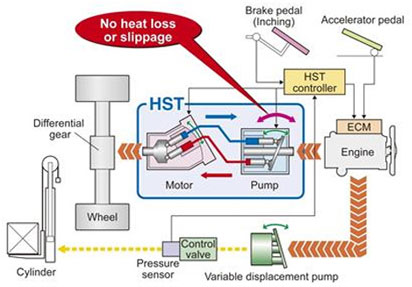

In the HST system, the diesel powered Hydrostatic Forklift engine drives the pump and oil supplied from the pump then rotates the motor that drives the forklift. The power losses over the entire engine speed range are minimal. Since the HST system does not have a clutch, there is no possibility of heat loss or slippage. This means power transmission losses are minimized to reduce fuel consumption.

- The FH series requires less inching pedal use because the HST forklift can adjust speed through the use of the accelerator pedal. Also with excellent controllability of the HST, the operator has better control when maneuvering in tight quarters, lifting, or load handling. Travel speeds can be set in for stages and activated with the turtle switch. To eliminate inadvertent start-ups, the FH engine can only start when the shift lever is set to neutral, brake pedal depressed and the operator is in the seat.

- With HST drive, the oil flow to the hydraulic motor is stopped when the accelerator pedal is released, so even if the forklift is stopped on a ramp and the operator releases the brake pedal, downhill creep is reduced. This also facilitates easier ramp-start.

Standard Travel Speed Limiter

- The feature ensures safe work by reducing speeds in tight spaces and keeping the forklift trucks within specific in-plant speed or environmental limitations.

- The FH series offers speed limiter settings for: 5 km/h, 8 km/h, 15 km/h, and 23.5 km/h.

- The travel speed limiter function can be switched on or off even while the machine is moving.

- Whether the travel speed limiter is on or off, the hydraulics speed remains the same.

- When carrying loads or traveling on slopes and unexpected deceleration occurs, a sensor will detect travel speed and maintain the preset speed.

- Administrators can only set maximum travel speeds. As a result there are both normal and maximum travel speed limits. This ensures safety when traveling between indoor and outdoor locations with different speed limits.